650V 10A Silicon Carbide (SiC) Schottky Diode with TO-252 Package TPDG10S65C1P Topdiode (IDK10G65C5)

- Positive temperature coefficient for safe operation and ease of paralleling

- Excellent surge capability

- Extremely fast, temperature-independent switching behavior

- Dramatically reduced switching losses compared to Si bipolar diodes

Topdiode 650V 10A Silicon Carbide (SiC) Schottky Diode with TO-252 Package TPDG10S65C1P (IDK10G65C5)

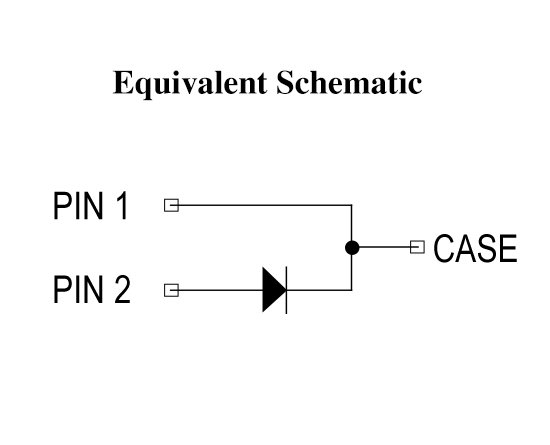

TOPDIODE TPDG10S65C1P is a SiC Schottky barrier diodes with TO-252 package.

This series of silicon carbide (SiC) Schottky diodes has negligible reverse recovery current, high surge capability, and a maximum operating junction temperature of 175 °C. These diodes series are ideal for applications where improvements in efficiency, reliability, and thermal management are desired.

Topdiode TPDG10S65C1P is a nice alternative offer for Littelfuse SiC Schottky barrier diodes LSIC2SD065C10A.

Topdiode 650V 10A Silicon Carbide (SiC) Schottky Diode with TO-252 Package TPDG10S65C1P DATA

- Tab

| Topdiode PN | TPDG10S65C1P |

| Description | SIC SBD |

| IFSM(A) | 65A |

| IF(AV) | 10A@148℃ |

| Vds | 650V |

| Package | TO-252 |

| Cross to Brand | Infineon |

| Pin to Pin Cross P/N | IDK10G65C5 |

Topdiode Hot Selling Products (6)

SiC Schottky Barrier Diode Datasheet

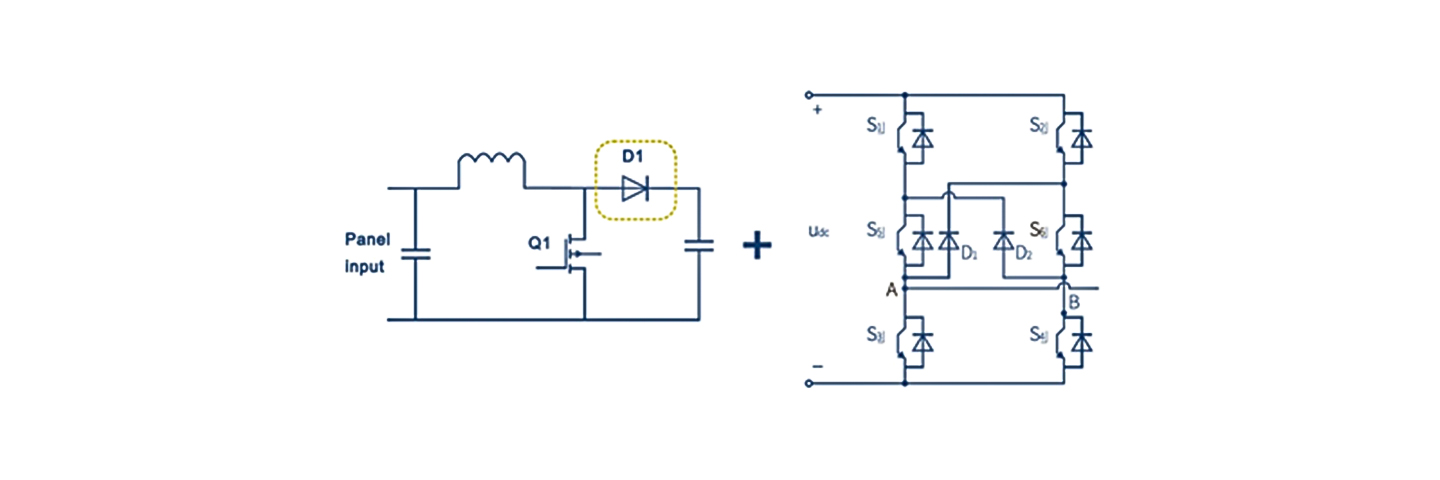

Topdiode SiC Schottky Barrier Diode Used on Photovoltaic Inverter

The advantage of solar power generation is that solar energy resources will never be exhausted, with zero emissions and a flexible layout of scales. Solar inverter is a kind of power electronic equipment that connects solar photovoltaic panels and the power grid. It first converts direct current into direct current to realize the maximum power tracking control function of solar energy, and then converts direct current into alternating current. By the number of AC output phases, it can be classified into single-phase inverters and three-phase inverters.

By electrical isolation, it can be classified into the isolated type and non-isolated type. According to the characteristics of inverters, a single-phase series inverter is selected for 220V projects, a three-phase series inverter is selected for 8KW-30KW projects, and a series inverter or centralized inverter can be selected for projects above 50KW according to the actual situation.

Traditional PV inverters must be matched with an isolation transformer, which usually reduces the efficiency by 2%. The new photovoltaic inverter adopts non-isolated inductance, featuring high power generation, high efficiency, small size and lightweight.

The SiC MOSFET and diode developed by APS will be an important force to promote inductor miniaturization with high frequency and low loss.

Topdiode Recommended Products:

SiC Diode:TPDB20A65C1P,TPDH40S65C1P,TPDH20S120C1P,TPDD40A120C1P,TPDH40S120C1P

Topdiode Silicon Carbide (SiC) Schottky Diode Applications

Silicon carbide (SiC), a semiconductor compound consisting of silicon (Si) and carbon (C), belongs to the wide bandgap (WBG) family of materials. Its physical bond is very strong, giving the semiconductor a high mechanical, chemical and thermal stability. The wide band gap and high thermal stability allow SiC devices to be used at junction temperatures higher than those of silicon, even over 200°C. The main advantage offered by silicon carbide in power applications is its low drift region resistance, which is a key factor for high-voltage power devices.

Silicon Carbide Schottky Barrier Diodes are semiconductor devices that consist of a metal contact on a layer of n-type Silicon Carbide (SiC) material. The metal contact forms a Schottky barrier with the SiC material, which allows the flow of current in only one direction. SiC Schottky barrier diodes offer several advantages over conventional diodes, including lower forward voltage drop, shorter reverse recovery time, higher breakdown voltage, and higher temperature operation

The working principle of a Silicon Carbide (SiC) Schottky diode is based on the metal-semiconductor junction known as the Schottky barrier. When a metal (typically aluminum or platinum) is deposited on a SiC substrate, a Schottky barrier is formed between the metal and the semiconductor material. Unlike traditional P-N junction diodes, the Schottky diode does not have a depletion region, which leads to a lower forward voltage drop and faster switching speed.

In forward bias, the metal contact is connected to the positive terminal of a voltage source, while the SiC substrate is connected to the negative terminal. When a positive voltage is applied, the electrons from the metal contact are injected into the SiC substrate, resulting in a flow of current through the device. The forward voltage drop in a SiC Schottky diode is typically lower than in a traditional P-N junction diode, which leads to lower power losses and higher efficiency.

In reverse bias, the metal contact is connected to the negative terminal of a voltage source, while the SiC substrate is connected to the positive terminal. When a negative voltage is applied, the Schottky barrier width increases, and the electric field across the device increases, leading to a breakdown of the device at a certain voltage, known as the reverse breakdown voltage. The reverse breakdown voltage of SiC Schottky diodes is typically higher than in traditional P-N junction diodes, which makes them suitable for high-voltage applications.

SiC Schottky diodes are used in a wide range of high-performance applications that require high temperature and high voltage operation, low power losses, fast switching speeds, and high efficiency. Some common applications of SiC Schottky diodes include:

Power Electronics: SiC Schottky diodes are used in power electronics applications, such as in switch-mode power supplies (SMPS), inverters, and motor drives. They help to reduce power losses, increase efficiency, and improve power density.

Automotive: SiC Schottky diodes are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to improve efficiency and extend the range. They are also used in battery chargers, DC-DC converters, and onboard chargers.

Aerospace and Defense: SiC Schottky diodes are used in aerospace and defense applications, such as in power supplies, motor drives, and electronic control units (ECUs). They help to reduce the weight, size, and complexity of the systems while improving reliability and performance.

Renewable Energy: SiC Schottky diodes are used in renewable energy systems, such as solar inverters and wind turbines. They help to improve efficiency, reduce the system cost, and increase the power density.

Consumer Electronics: SiC Schottky diodes are used in consumer electronics applications, such as laptops, smartphones, and tablets. They help to improve the battery life, reduce the charging time, and increase power efficiency.

Our SiC Schottky Barrier Diodes (SBDs) increase efficiency and add superior reliability in high-voltage applications. SiC diodes exhibit higher breakdown voltage with a lower forward voltage drop and a significantly shorter reverse recover time. SiC SBDs are designed with balanced surge current, forward voltage, thermal resistance and thermal capacitance ratings at low reverse current for lower switching loss, enabling more efficient power systems.