High-Voltage Rectifier Diodes in Power Supplies, Inverters, Industrial Control, and Home Appliances

Rectifier diodes are among the most widely used components in power electronics. Although they are often considered “basic parts,” their selection directly affects efficiency, thermal performance, EMI behavior, and long-term reliability. In applications such as AC/DC power supplies, inverters, industrial control systems, and home appliances, rectifier diodes must withstand repetitive reverse voltage stress, handle surge current at startup, and remain stable under elevated temperature conditions.

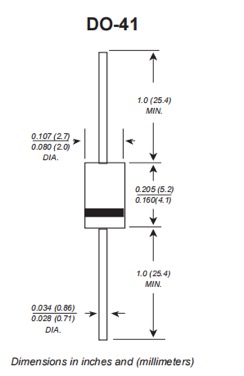

1.Why DO-41 Rectifiers Are Still Popular

The DO-41 axial package remains a mainstream solution due to its balanced performance and manufacturing convenience. Compared with smaller signal diode packages, DO-41 provides improved mechanical strength, higher power dissipation capability, and stable soldering performance for through-hole assembly. The cathode band marking also simplifies polarity identification and reduces assembly errors.

For many cost-sensitive and high-reliability products, DO-41 rectifiers continue to be a preferred choice for:

AC to DC rectification

Freewheeling and commutation paths

Reverse polarity protection

General power switching functions

2. Typical Applications

2.1 AC/DC Power Supplies

In offline power supplies, rectifier diodes are often used in:

Input bridge or half-wave rectification

Auxiliary power circuits

Secondary-side rectification (low-frequency rails)

The key requirements include stable reverse voltage margin, predictable thermal behavior, and surge capability during capacitor charging.

2.2 Inverters and Motor Drives

In inverters and motor drive systems, rectifiers may appear in:

Control power supplies

Snubber or clamp networks

Protection circuits

These systems often operate under high electrical noise, high temperature, and switching transients. Choosing a diode with strong reverse withstand capability helps reduce unexpected breakdown risk.

2.3 Industrial Control and Automation

Industrial control boards often require long-term stability in harsh environments. Rectifier diodes used in input power, relay driving, or protection circuits must maintain performance under continuous operation and temperature cycling.

2.4 Home Appliances

Appliances such as air conditioners, washing machines, induction cookers, and microwave ovens contain multiple rectification and protection stages. In these designs, reliability and production consistency are essential, especially for high-volume manufacturing.

3. Reverse Voltage Rating: The First Critical Parameter

The reverse voltage rating is a fundamental factor when selecting rectifier diodes. In real systems, the reverse voltage across a diode is not always equal to the nominal mains voltage. It can be significantly higher due to:

Line surges

Inductive load switching

Transformer leakage inductance ringing

Fast recovery behavior of surrounding devices

For this reason, engineers typically select rectifier diodes with adequate voltage margin above the expected peak reverse voltage. The TOPDIODE EM513–EM518 series offers high-voltage options within the same DO-41 family, supporting a wide range of design needs up to the 2kV level.

A conservative voltage selection improves field reliability, especially for industrial and inverter systems exposed to frequent electrical transients.

4. Forward Current vs. Real Thermal Limits

Many designers focus on rated average forward current, but the real limitation often comes from thermal conditions. Junction temperature depends on:

Conduction loss (IF × VF)

Ambient temperature

PCB and lead heat dissipation

Airflow and enclosure design

In compact power supplies and appliance control boards, airflow may be limited. Even if the diode current is below its nominal rating, poor thermal dissipation can cause excessive junction temperature rise.

The derating curve provides a useful reference for estimating allowable current at higher ambient temperatures and helps prevent overheating during long-term operation.

5. Surge Current Capability: A Hidden Reliability Factor

Surge current is often overlooked, yet it is one of the most common causes of rectifier diode stress. Typical surge events include:

First power-on charging of bulk capacitors

Transformer magnetizing inrush

Short transient overload conditions

Repetitive power cycling

A diode with strong surge capability provides additional safety margin against occasional high-current pulses. This becomes particularly important in industrial power supplies and appliances that may be frequently switched on and off.

6. Forward Voltage Drop: Efficiency and Heat Generation

Forward voltage drop is directly related to conduction loss and heat generation. In low-frequency rectification, silicon rectifiers typically show a forward drop around 1V at rated current. While this is acceptable in many applications, designers should evaluate:

Expected operating current range

Thermal rise in the enclosure

Efficiency targets

For low-voltage, high-current rails, Schottky rectifiers may reduce conduction loss. However, in higher-voltage applications, standard silicon rectifiers remain advantageous due to their strong reverse withstand capability and stable operating behavior.

7. Reverse Leakage: Especially Important at High Temperature

Reverse leakage current increases as temperature rises. In industrial control systems, power cabinets, and inverter environments, ambient temperature may be significantly higher than standard room conditions. Excessive leakage can lead to:

Additional power loss

Increased heat generation

Unexpected behavior in sensitive circuits

Selecting a diode series with stable leakage performance and providing sufficient thermal margin helps ensure consistent operation over the product lifetime.

8. Junction Capacitance and Switching Behavior

Although general purpose rectifiers are not optimized for ultra-fast switching, junction capacitance still plays a role in EMI behavior and transient response. In some power circuits, diode capacitance can influence:

Switching noise coupling

Transient voltage overshoot

Ringing behavior

Understanding capacitance trends helps designers improve EMI robustness, especially in inverter-related circuits.

9. Practical Selection Checklist (Engineer-Friendly)

When choosing a DO-41 rectifier for power supplies, inverters, industrial control, or home appliances, consider the following checklist:

Reverse voltage margin

Choose sufficient VRRM margin for surges and transients.

Average current vs thermal design

Verify current derating based on real ambient temperature and airflow.

Surge current capability

Ensure the diode can survive inrush and capacitor charging pulses.

Forward voltage and power loss

Estimate conduction loss and confirm safe junction temperature.

Leakage at high temperature

Confirm stability under hot operating conditions.

Mechanical and assembly reliability

Ensure stable soldering performance for mass production.

In modern power electronics, rectifier diodes continue to play a vital role in reliability and performance. For designs in AC/DC power supplies, inverters, industrial control systems, and home appliances, selecting a robust DO-41 rectifier with sufficient voltage margin, strong surge capability, and predictable thermal behavior is essential.

TOPDIODE EM513–EM518 DO-41 general purpose rectifiers offer a practical solution for high-voltage rectification and protection needs across a wide range of applications. For faster part selection, cross-reference support, and sample requests, please contact TOPDIODE sales for technical assistance.