Aluminum Capacitors—The Essential Guide to Passive Component Fundamentals

Introduction to Aluminum Electrolytic Capacitors

Aluminum capacitors, also known as aluminum electrolytic capacitors, represent one of the most fundamental and widely used passive components in modern electronics. Characterized by their cylindrical shape with polarity markings, these components have become indispensable in circuits requiring substantial capacitance values in relatively compact packages. Their unique construction—featuring an aluminum anode, electrolyte-soaked paper separator, and aluminum oxide dielectric layer—enables them to deliver performance characteristics that make them particularly suitable for specific electronic applications.

Key Features and Technical Advantages

High Capacitance Density

Aluminum capacitors offer exceptionally high capacitance values relative to their physical size and cost, typically ranging from 1μF to several thousand microfarads. This makes them ideal for applications requiring substantial energy storage in limited spaces.

Polarity-Sensitive Design

As polarized components, they must be correctly oriented in circuits. Modern variants often include clear polarity markings and safety vents to prevent catastrophic failure.

Voltage Range Flexibility

Available in working voltages from 6.3V to several hundred volts, aluminum capacitors accommodate diverse circuit requirements across low-voltage digital systems to high-power industrial equipment.

Temperature Performance

Standard versions operate effectively from -40°C to +85°C, with specialized high-temperature variants extending to +125°C or higher for demanding environments.

Primary Applications in Modern Electronics

Power Supply Systems

- Input/Output Filtering: Smoothing rectified AC voltage in power supplies

- Energy Storage: Providing temporary power during voltage dips

- Decoupling: Stabilizing voltage levels in DC power distribution networks

Consumer Electronics

- Televisions, audio amplifiers, and home entertainment systems

- Computer motherboards and graphics cards

- Power adapters and battery charging circuits

Industrial and Automotive Applications

- Motor drive circuits and industrial control systems

- Automotive infotainment and engine control units (ECUs)

- Renewable energy systems (solar inverters, wind turbines)

Lighting Technology

- LED driver circuits and ballasts

- Strobe lighting and camera flash systems

Selection Considerations and Best Practices

Voltage Rating Selection

Always choose capacitors with voltage ratings at least 20-50% higher than the maximum expected operating voltage to ensure reliability and longevity.

Capacitance Tolerance

Standard aluminum capacitors typically offer ±20% tolerance, with premium versions available at ±10% for precision applications.

ESR (Equivalent Series Resistance) Considerations

Lower ESR values are crucial for high-frequency applications and switching power supplies. Consider polymer aluminum capacitors for ultra-low ESR requirements.

Lifetime and Temperature Factors

Operating temperature significantly impacts lifespan. For every 10°C reduction below maximum rated temperature, lifetime typically doubles according to Arrhenius’ law.

Physical Size Constraints

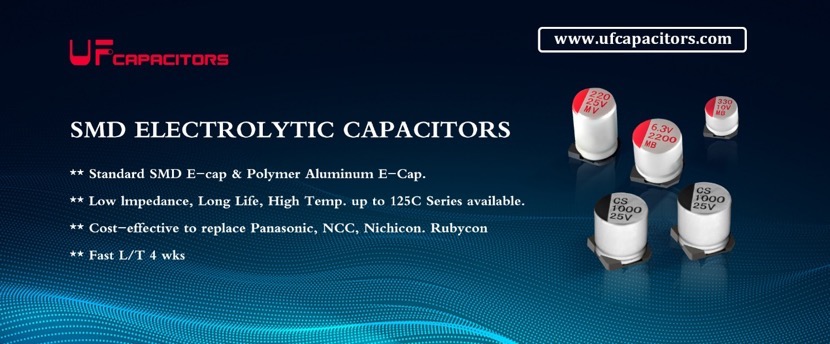

Consider both diameter and height when selecting capacitors, particularly in space-constrained designs. Surface-mount (SMD) versions offer space-saving advantages.

Common Failure Modes and Prevention

Electrolyte Drying

The primary failure mechanism involves gradual electrolyte evaporation over time. Mitigate through proper derating and thermal management.

Voltage Overstress

Exceeding rated voltage causes rapid deterioration. Implement protective circuits and proper voltage margin selection.

Reverse Polarity Application

Even brief reverse voltage application can cause immediate failure. Double-check polarity during installation and design phases.

Mechanical Stress

Excessive board flexure or vibration can damage internal connections. Use proper mounting techniques and consider ruggedized variants for harsh environments.

Emerging Trends and Future Developments

Hybrid and Polymer Technologies

Modern aluminum capacitors increasingly incorporate conductive polymer electrolytes, offering lower ESR, longer lifespan, and improved temperature stability.

Miniaturization Advances

Continued development delivers higher capacitance in smaller packages, supporting the trend toward increasingly compact electronic devices.

Enhanced Environmental Compliance

RoHS-compliant, lead-free versions with improved recycling characteristics address growing environmental concerns and regulatory requirements.

The Enduring Relevance of Aluminum Capacitors

Despite the emergence of alternative capacitor technologies, aluminum electrolytic capacitors maintain their vital position in electronic design due to their unique combination of high capacitance, cost-effectiveness, and proven reliability. By understanding their characteristics, limitations, and proper application principles, engineers can effectively leverage these components to create robust, efficient electronic systems across countless applications.