Si vs. SiC: Material Differences & Benefits

Previously, we have seen that the MOSFETs constructed with SiC demonstrate superior performance over the conventional Si MOSFETs. Now we delve deep into understanding why this is the case:

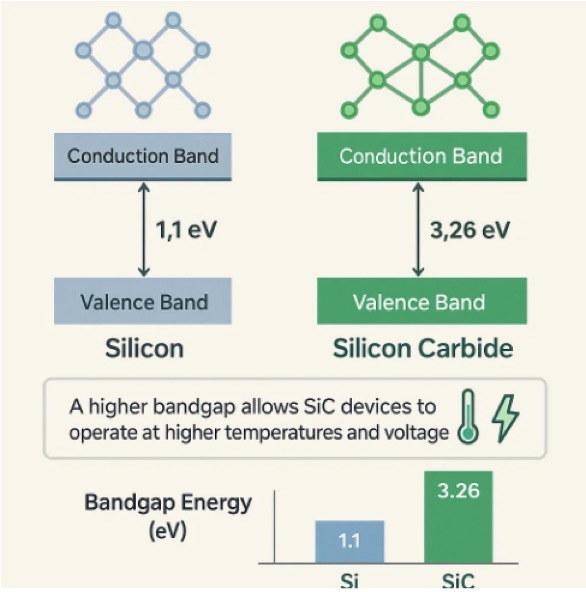

Higher Bandgap Energy

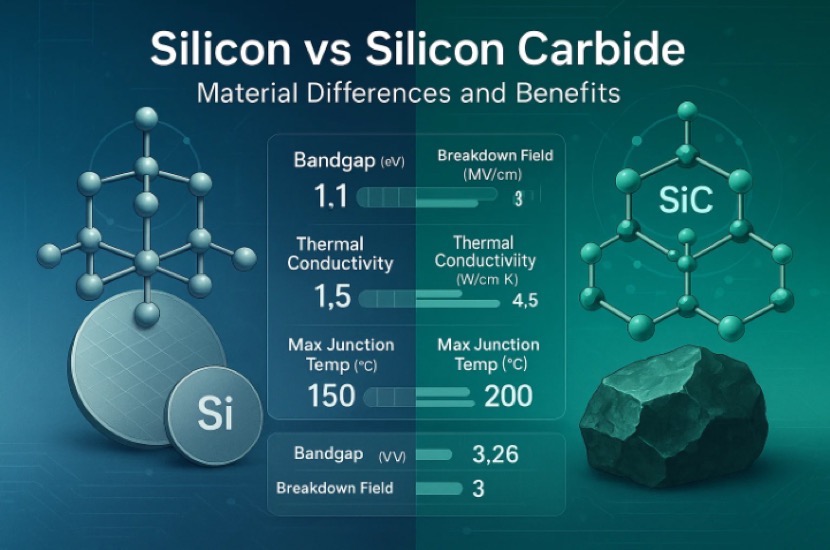

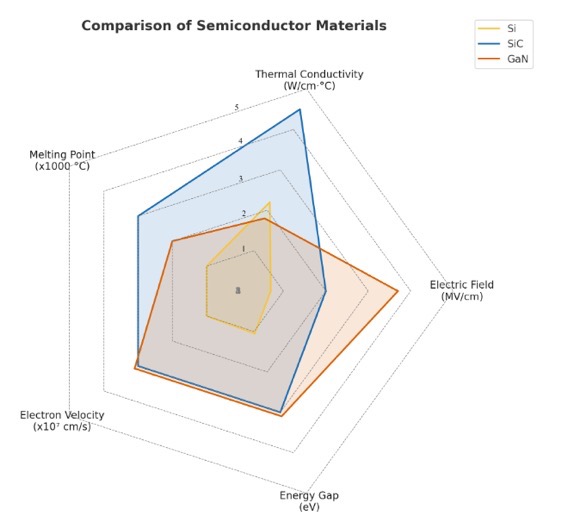

Silicon Carbide semiconductor (SiC) is a wide-bandgap energy semiconductor. Simply put, Silicon carbide can withstand much more energy the Silicon before it breaks down. In numbers, Silicon Carbide has 3.26 eV bandgap energy compared to 1.12 eV of Silicon. So, the Silicon Carbide has almost 3 times the bandgap energy that of Silicon.

The higher bandgap energy of Silicon Carbide directly translates into SiC MOSFETs’ ability to operate in higher temperatures and withstand stronger electric fields compared to silicon-based MOSFETs.

Silicon Carbide semiconductors can operate between 175 °𝐶–200 °𝐶 junction temperature, which is much more than silicon-based transistors rated for a maximum 150 °𝐶. The higher temperature bearing capacity enables SiC-based MOSFETs to operate at very high temperatures, such as in aerospace, automotive under the hood, and downhole drilling applications.

Higher Breakdown Electric Field

Silicon Carbide semiconductor has a much higher breakdown electric field than Silicon. In terms of numbers, the SiC material can handle 2 – 4 MV/cm electric field, which is approximately an order of magnitude more than Silicon. Engineers can manufacture thinner and more heavily doped devices using Silicon Carbide, thanks to its ability to withstand much higher voltage per centimeter than silicon.

Commercial SiC MOSFETS can operate between 1200 V – 1700 V, whereas Si MOSFETs would tap out at 900 V, and the designer had to opt for IGBT beyond 600 V applications. Effectively, designers build much sturdier and more efficient, high-voltage MOSFETs (SiC MOSFETs) using Silicon Carbide rather than with Silicon.

High Thermal Conductivity

In addition to Silicon Carbide’s ability to perform flawlessly under higher temperatures, Silicon Carbide semiconductor has superior thermal conduction (3x Si) compared to Si-based semiconductors.

Better thermal conduction means better heat dissipation and less thermal resistance. SiC’s superior thermal conduction has a direct effect on reduced thermal runaway resistance compared to equivalent Silicon devices. SiC’s better thermal performance enables designers to choose slimmer heatsinks and simpler cooling systems in condensed circuit design.

Faster Switching Speed

As we have already elaborated in detail on our blog MOSFET vs IGBT, the MOSFETs conduct through majority carriers only. Majority carrier conduction allows MOSFETs to switch faster than IGBTs’ bipolar conduction. They already have lower losses at higher temperatures.

Due to superior switching speed to IGBTs, MOSFETs offer higher PWM frequencies in applications such as DC Motor Speed Controller Circuits, effectively allowing slimmer magnetics (inductors, transformers) and capacitance, reducing the overall circuit size and weight.

From the superior properties of Silicon Carbide described above, we can see that silicon carbide semiconductor material is harder, faster, and can sustain higher temperatures optimally. However, the benefits of the SiC are not without drawbacks.

SiC’s material has higher hardness, and during its crystal stage, the early-stage crystal defects (e.g., dislocations, interface oxide issues) had made the fabrication relatively more complex and cost higher than the traditional Si processing.