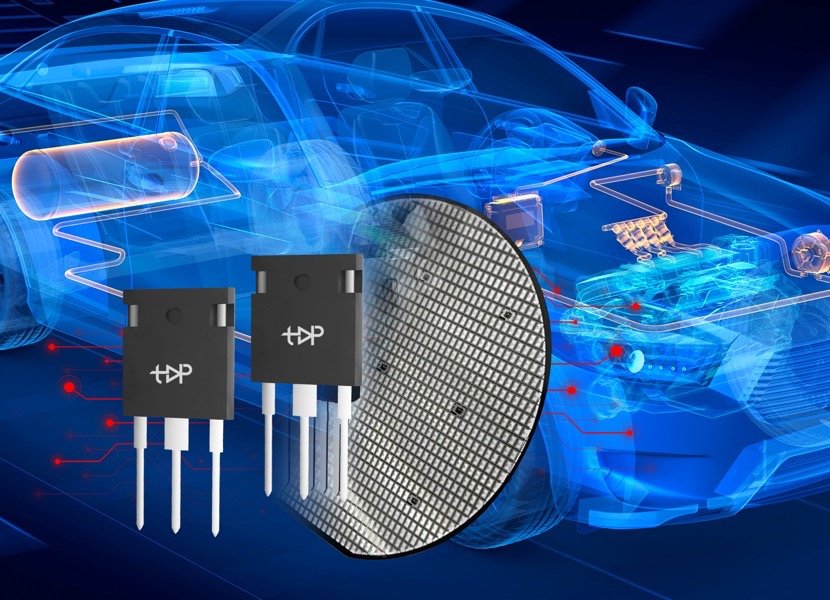

Topdiode the 4th SiC MOSFETs

The latest advancement in Silicon Carbide (SiC) technology, the 4th generation SiC MOSFETs, are poised to disrupt the power electronics industry. Building upon the success of their predecessors, these new devices offer significant improvements in efficiency, performance, and reliability.

Their popularity has surged in recent years, particularly in the power electronics domain, where compactness, efficiency, and reliability are paramount. Specifically, the SiC MOSFET market has witnessed rapid growth in recent years, driven primarily by the electric vehicle (EV) industry.

The fourth generation SiC MOSFET has produced notable advancements in areas like decreased energy losses, quicker switching speeds, and increased potential for power system miniaturization.

4th Gen SiC MOSFET features

Four features distinguish Topdiode’s 4th generation SiC MOSFETs:

- Low on-resistance

- SCWT robust

- Minimized switching losses from reduced parasitic capacitance

- Simple gate drive design

The 3th Gen SiC MOSFETs/The 4th Gen SiC MOSFETs comparison

Compared to 3rd generation SiC MOSFETs, 4th generation devices boast a drastic reduction in on-resistance and switching losses. This translates to even lower energy consumption and heat generation, leading to more efficient power conversion and potentially smaller cooling systems.

Benefits for Real-World Applications

The advancements of 4th generation SiC MOSFETs translate into tangible benefits for various applications:

Electric Vehicles (EVs): Higher efficiency and faster switching speeds lead to improved range and faster charging times for EVs. Additionally, the ability to handle higher power densities allows for the development of more compact and lightweight on-board chargers and inverters.

Renewable Energy Systems: Increased efficiency in solar and wind power inverters contributes to maximizing energy capture and reducing system losses. The compact size and reliability of 4th generation SiC MOSFETs are also advantageous for these applications.

Industrial Power Supplies: Industrial applications demanding high power and efficiency can benefit significantly from 4th generation SiC MOSFETs. Their ability to operate at higher temperatures and frequencies allows for more robust and efficient power conversion in harsh industrial environments.

Data Centers: The ever-increasing power demands of data centers necessitate highly efficient power conversion solutions. 4th generation SiC MOSFETs contribute to lower energy consumption and potentially smaller and more manageable data center footprints.

The Future of Power Electronics

The introduction of 4th generation SiC MOSFETs marks a significant step forward in power electronics technology. With their exceptional efficiency, performance, and reliability, these devices pave the way for the development of more compact, efficient, and reliable power electronics systems across various industries. As SiC technology continues to mature and costs decrease, we can expect 4th generation SiC MOSFETs to become the new standard for demanding power conversion applications.

For further question or inquiries, please kindly contact Loie: sales4@topdiode.com, or visit our website: www.topdiodes.com thanks