Understanding Silicon IGBTs and Silicon Carbide MOSFETs

Both Silicon Carbide MOSFET vs Si IGBT, are switching devices that can handle varying degrees of voltage, current and operate at specified switching frequency. However, as we have seen in our detailed blog on MOSFET vs IGBT, typical MOSFETs are suitable for high-frequency applications. MSOFETs are also capable of handling low to moderate currents and voltages. On the other hand, IGBTs are better suited for high voltage, high DC, or continuous current.

The clear distinction between MOSFETs and IGBTs begins to blur when we change the construction material of MOSFETs from Si (Silicon) to SiC (Silicon Carbide).

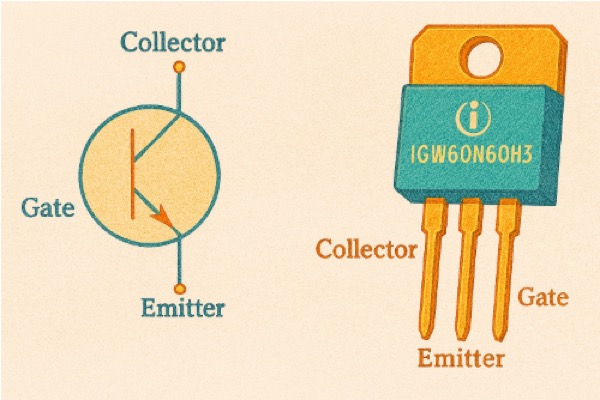

Si IGBT

A conventional IGBT (also called a Si IGBT) has three terminals similar to the MOSFET, with different names, though. The IGBT terminals are called Gate, Collector, and Emitter as demonstrated in the following structure, and visual image of the IGBT:

Similar to the Si MOSFET, the Si IGBT is voltage-driven at the Gate, but with a defining difference that the IGBT conducts using both the minority and majority carriers in the material. Because of this bipolar conduction, the Si IGBTs turn-off slowly due to stored charge (also called the “tail current”). This tail current restricts the Si IGBT’s switching frequency, making it a good fit only for slow switching frequency applications compared to the Si MOSFETs.

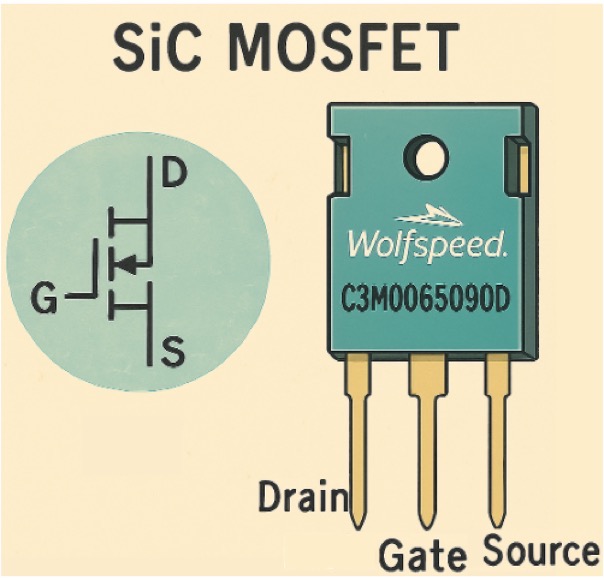

SiC MOSFET

Silicon Carbide MOSFETs (SiC MOSFETs) are not drastically different from conventional Si MOSFETs in terms of their core functionality, and have the same number of functional pins: Gate, Drain, and Source. Likewise, they both are controlled using a voltage-operated insulated Gate. SiC MOSFETs are also unipolar devices that conduct using majority carriers, allowing faster switching speeds.

The SiC MOSFET operates on the same principle of conduction when the gate voltage reaches a specific threshold level. However, due to SiC material’s capabilities, the SiC MOSFET can handle much higher temperatures and voltages than the Si MOSFET. Previously, the particular reason why Si MOSFETs were dropped in favor of IGBT was the large voltage drop across MOSFET’s 𝑅𝐷𝑆(𝑜𝑛) at a very high current. This shortcoming is remedied using SiC material for SiC MOSFET construction, which allows a similar lower voltage drop at higher currents as the traditional IGBTs. Hence, MOSFETs once again became viable option for high-power applications.

Essentially, the SiC MOSFETs merge the gate control and fast switching of traditional MOSFETs with the high-power capacity of traditional IGBTs. Effectively, SiC MOSFETs rival the traditional IGBT due to better construction material.