What is the difference between an IGBT and a MOSFET?

IGBTs(Insulated Gate Bipolar Transistors) and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are both types of semiconductor devices, but they have different characteristics and are suitable for different applications.

MOSFET

The MOSFET is a field-effect transistor that is comprised of three components: a source, drain, and gate. The MOSFET works by varying the width of a channel between the source and drain nodes along which charge carriers flow. The voltage that is applied across the gate controls the size of the channel which determines the current flow into the drain. MOSFETs only have 2 layers of P and N type substrate which lowers their voltage capacity as compared to IGBTs but allows them to handle faster switching speeds. More recent MOSFETs have been able to handle much higher voltages, but this comes with increased size and cost. MOSFETs are commonly used in automotive electronics and robotics because of their fast-switching speeds. MOSFETs can also be used for many industrial applications depending on voltage and switching conditions.

IGBT

The IGBT is a bipolar transistor, also comprised of three components: an emitter, collector, and gate. IGBTs have the high-current and low-saturation-voltage input capabilities of bipolar transistors with the output characteristics of MOSFET. Unlike MOSFETs, IGBTs are current controlled, producing a magnetic field rather than an electric field and a minority carrier dominant current. IGBTs have multiple layers of P and N substrate which give them the advantage of handling high voltages as compared to the MOSFET. These extra layers come with the disadvantage of lower switching speeds, however, innovations in IGBT technology have allowed these transistors to have switching speeds comparable to MOSFET. IGBTs are used in many industrial and automotive applications and tend to be preferred for home appliances such as air conditioning units and refrigerators. Like MOSFETs, the specific applications of IGBTs depend on voltage and switching conditions.

Comparing MOSFET vs IGBT

| MOSFET | IGBT | |

| Construction Similarities | Comprised of P and N type substrates to allow and control the flow of current | |

| Construction Differences | Two layers of P and N type substrate assists in high switching frequency, contains body-drain diode |

Multiple layers of P and N substrate give IGBT high conductivity, does not have body drain diode |

| Control | Voltage driven majority carrier devices, produces an electric field |

Current controlled minority carrier devices, produces magnetic field |

| Uses | Can be used in digital and analog drives, both are used in off-the-shelf and custom servo drives. Their small sizes have led to the possibility of smaller servo drives such as the uZ series | |

| Interface Similarities | Three terminal transistors comprised of a relatively simple gate drive circuit | |

| Interface Differences | Source, Drain, Gate | Emitter, Collector, Gate |

| Operating Voltage | Typically <250V | Capable of >1000V |

| Switching Frequency | High +100kHz | Low ~20kHz |

Choose MOSFET for

- Low Voltage/High Frequency:Ideal for <50V and switching in the MHz range (e.g., SMPS, DC-DC converters).

- Fast Switching:Faster turn-off, lower switching losses at high frequencies.

- Lower Cost:Generally cheaper for low-to-medium power systems.

Choose IGBT for

- High Voltage/High Power:Handles higher voltages and currents more efficiently.

- Industrial Applications:Excellent for motor drives, welding, and large power systems where ruggedness is key.

- Lower Switching Frequency:Better suited for <20kHz applications.

Key Differences Summary

- Structure:IGBTs add a p-substrate layer, allowing for higher current density but creating a slower turn-off (tail current).

- Efficiency:MOSFETs have lower on-resistance at low currents; IGBTs have lower on-state voltage drop (Vce(sat)) at high currents, meaning lower conduction loss.

- Performance:MOSFETs = fast, efficient at low power; IGBTs = rugged, efficient at high power.

Is It Possible to Use IGBT In Place Of MOSFET?

Both IGBTs and Power MOSFETs are used for switching applications in power electronics, and they have some similarities and differences.

IGBTs are preferred in high-power applications because of their lower conduction losses, which allows for higher efficiency and lower heat dissipation.

In contrast, Power MOSFETs are typically preferred for lower voltage and lower power applications because of their faster switching speeds and simpler drive circuitry requirements.

However, some design considerations need to be taken into account when replacing a Power MOSFET with an IGBT.

For example, IGBTs have a higher gate capacitance, which can affect switching times and require a more powerful gate driver circuit.

IGBTs also have a higher voltage drop than Power MOSFETs, which can result in higher power dissipation and temperature rise.

Overall, the decision to use an IGBT or a Power MOSFET will depend on the specific requirements of the project, including voltage, current, switching speed, and efficiency.

It is important to carefully evaluate the specifications of both devices and consider the trade-offs before making a decision.

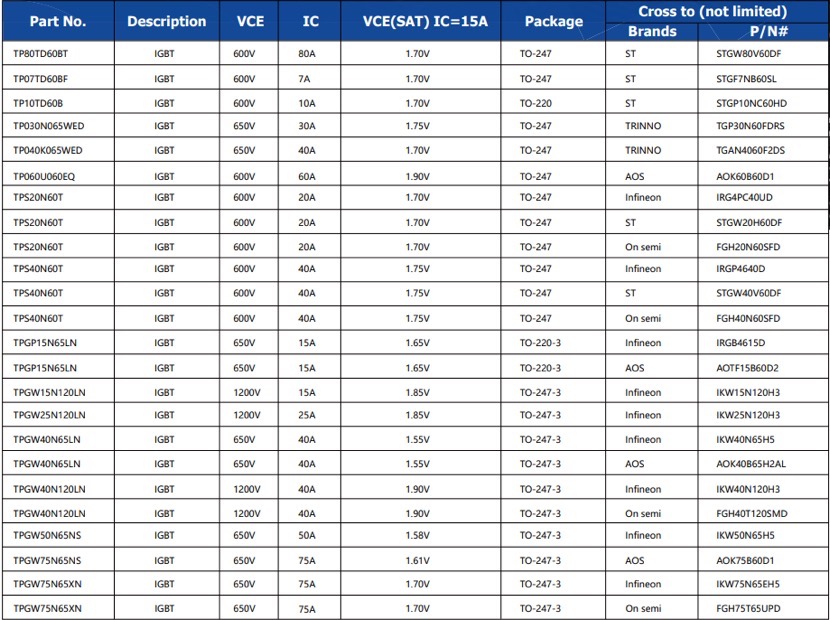

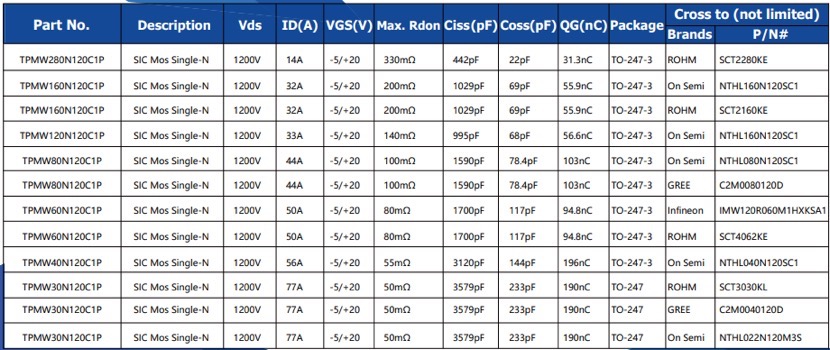

Topdiode provide cost effective IGBTs and MOSFET

To replace Infineon, Onsemi, AOS, and ST IGBT, used in various industries such as automotive, solar energy, 5G telecommunications, industrial electronics, white goods, lighting, security, and consumer electronics.

For more information, please visit https://www.topdiodes.com/