IGBT vs. MOSFET: Key Technologies in Power Electronics

In the field of power electronics, two of the most critical semiconductor devices are the MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and the IGBT (Insulated Gate Bipolar Transistor). Both are essential for controlling the flow of electrical energy in a wide range of applications, but their design, performance characteristics, and ideal use cases differ significantly. Understanding these differences is crucial for engineers selecting the right component for a given application.

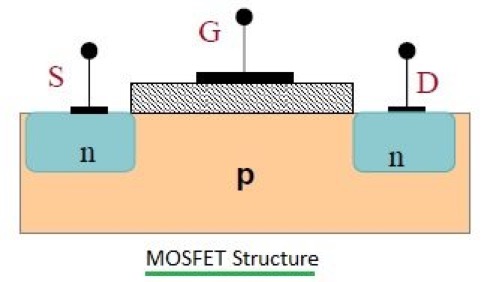

MOSFET: Origin, Structure, and Operation

The MOSFET originated in the mid-20th century during a period of rapid innovation in electronics. It is a four-terminal device with source (S), drain (D), gate (G), and body (B) terminals. Typically, the body is tied to the source, effectively reducing it to a three-terminal device. The MOSFET operates by using an electric field to control conductivity in a semiconductor channel, which is the essence of its name.

MOSFETs are known for their high switching speed and low on-resistance (Rds(on)), making them ideal for low- to medium-voltage applications. However, high-power MOSFETs can be prone to thermal runaway if not managed carefully.

Advantages of MOSFETs

Very fast switching speed, enabling high-frequency operation

Low conduction losses at lower voltages

Simple gate drive requirements due to high input impedance

Limitations of MOSFETs

Susceptible to thermal instability at high power levels

Conduction losses increase rapidly at high current levels

Less robust under short-circuit conditions compared with IGBTs

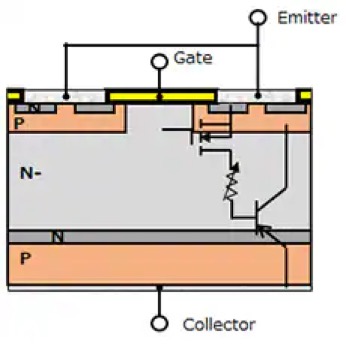

IGBT: Origin, Structure, and Operation

The IGBT is a more recent development, combining features of the MOSFET and the BJT (Bipolar Junction Transistor). It merges the high input impedance of the MOSFET with the low saturation voltage of the BJT. As a result, the IGBT provides excellent performance in high-voltage, high-current applications.

Advantages of IGBTs

Low saturation voltage, reducing conduction losses in high-voltage systems

Better thermal stability, less prone to runaway

High robustness, especially in short-circuit conditions

Limitations of IGBTs

Slower switching speeds compared with MOSFETs

Higher switching losses, limiting their use in high-frequency applications

More complex gate drive requirements

Comparing MOSFETs and IGBTs

The choice between MOSFETs and IGBTs depends on the specific requirements of the application. Key factors to consider include:

Rated Voltage:

MOSFETs are more efficient below ~200V due to their very low Rds(on).

IGBTs are better suited for applications above 600V where conduction efficiency and robustness are critical.

Switching Speed:

MOSFETs switch faster, making them ideal for high-frequency designs such as DC-DC converters and SMPS.

IGBTs switch slower, but this is generally not an issue in low-frequency motor drives or grid applications.

Conduction and Switching Losses:

MOSFETs exhibit lower switching losses but higher conduction losses at high current.

IGBTs have lower conduction losses at high current but higher switching losses.

Ruggedness:

IGBTs are typically more robust under fault conditions.

MOSFETs are less tolerant to short circuits but excel in efficiency.

Driver Complexity:

MOSFETs are easier to drive thanks to their simple gate requirements.

IGBTs may require more complex gate driver circuitry in high-voltage systems.

Real-World Applications

MOSFET Applications

Switching Power Supplies: Widely used in SMPS and DC-DC converters thanks to fast switching and low conduction losses.

Motor Drivers and Battery Management Systems: Provide efficient switching control for automotive and industrial systems.

Amplifiers: High input impedance makes MOSFETs suitable for RF amplifiers and audio amplifiers.

Digital Logic Circuits: CMOS technology, based on MOSFETs, underpins modern microprocessors, memory, and digital ICs.

Electric and Hybrid Vehicles: Applied in BMS and auxiliary motor control systems.

RF and Communication Devices: MOSFETs amplify signals in mobile phones, routers, and wireless systems.

IGBT Applications

Inverters for Motor Drives: Used in elevators, pumps, fans, and industrial automation systems.

Electric and Hybrid Vehicles: Powering traction inverters and charging systems.

Power Grids: Integral to HVDC systems, FACTS, and large-scale UPS systems.

Renewable Energy: Inverters for solar and wind systems converting DC into AC.

PCB Manufacturing: High-frequency pulsed operation in drilling equipment.

Power Tools: Providing speed and torque control in electric drills, saws, and chainsaws.

Which is Better: IGBT or MOSFET?

Neither device is inherently “better” than the other; the choice depends on system requirements.

For low-voltage, high-frequency applications (below 200V, tens to hundreds of kHz), MOSFETs are superior.

For high-voltage, high-current applications (600V and above, lower frequencies), IGBTs are the preferred choice.

MOSFETs and IGBTs are complementary technologies. Each brings unique advantages that suit particular power electronic systems. The engineer’s task is to carefully weigh switching speed, voltage and current requirements, conduction efficiency, and thermal management to select the most appropriate device.